Food safety is not short on data. What it has always struggled with is how humans interact with that data under pressure — audits, incidents, regulatory changes, and operational constraints that leave little room for experimentation.

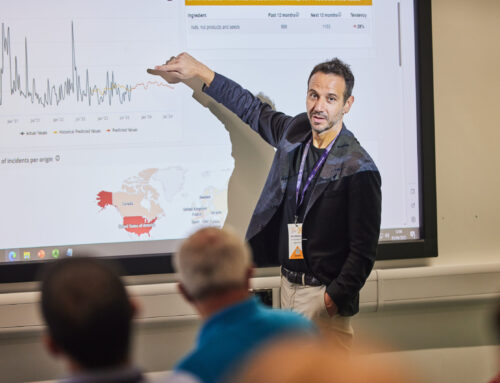

That tension was the starting point for the Food & Intel Fireside Chats: a video podcast series created to host practical, honest conversations about digital food safety, AI, and the realities faced by people working in the field. Not vendor demos. Not hype. Just experienced practitioners thinking out loud about what is actually changing — and what still isn’t.

For the inaugural episode, I had the pleasure of hosting Erik Westblom, CEO of Provision Analytics. Our discussion focused on how AI might help simplify complexity in food safety operations — without losing trust, usability, or accountability along the way.

Rather than chasing abstract promises, the conversation revolved around how AI could reduce friction in everyday food safety workflows; how food safety software may evolve beyond static forms and reports; why usability and adoption matter as much as technical capability; how compliance can be strengthened through risk intelligence while respecting data governance and privacy; and why the industry continues to wrestle with the balance between standardization and customization as requirements fragment.

Where does AI come into play in the world?

I think we’re still at the bottom of that inflection point. The industry is only now becoming familiar with pragmatic, general-purpose tools like ChatGPT — tools we already use internally all the time.

The real question is how you extrapolate something like that and apply it meaningfully to food safety — at product level, at system level, at scale. Only after that do you start looking at the more complicated things.

Can you give me a concrete use case where large language models could be useful for users?

A good example would be audit preparation. Imagine asking the system: “Prepare my audit. Give me all paperwork for the last year related to packing, cooling, and storage for this product.”

Instead of manually configuring reports, searching through binders, spreadsheets, or folders, you could pull that information dynamically from your database, in real time, in whatever format is required — bullets, long-form, or regulator-ready.

So the complexity of regulatory requirements is hidden inside the question itself?

Exactly. The intent expressed in the question already contains the structure of the requirement. The system understands the standard, retrieves the right data across workflows and timeframes, and assembles something acceptable to the inspection authority.

What changes is not just speed, but the interface: less time translating rules into screens and reports, more time understanding what the data actually says.

How does this scale as standards and customer requirements keep changing?

Large buyers and retailers increasingly introduce their own variations on core food safety standards. What used to be one audit format now has many versions.

Instead of hand-crafting reports endlessly, there’s an opportunity to train models on expectations — and let them dynamically organize the information based on who’s asking and why.

Want to know more?

You can watch the discussion on our YouTube channel here or listen to it on Spotify here.