Things are changing so fast in the food sector. Food safety has emerged as a critical topic that is high in the agenda of consumers, governments and the food industry alike. It took a series of food safety scandals and public health incidents for the industry to take some serious steps in establishing a food safety culture and align its standards through the Global Food Safety Initiative (GFSI). Governments are also applying stricter policy and legislation, such as the integrated Food Safety policy of the European Commission and the US Food Safety Modernization Act (FSMA). There is so much pressure for all stakeholders in the food supply chain to ensure that food is clean, healthy and safe.

This is changing the global landscape in the food market. There are companies that will evolve, comply and survive. There are companies that will innovate, pioneer and lead. There are also those companies that will eventually struggle to keep up and become extinct.

On the other hand, complying to new, stricter food safety requirements and legislation is a really tough nut to crack. Food certification requires extensive data logging and documentation. It calls for information about the way every supplier in a supply chain controls each and every type of potential risk (e.g. chemical, biological, fraud). This is not an easy task for the hundreds of thousands of small and medium enterprises supplying the global market with food.

To give you an example, every time a buyer or inspector requests access to the supportive information behind a food supplier’s certificate, they usually rely on the documentation and complementary data that the supplier is providing: a copy of the certificate application, a spreadsheet with the monitoring measurements they took on the production line, the results from testing product samples in an accredited laboratory etc. Not being able to trust the certificate and its supporting information adds an extra cost to the process. For instance, the buyer will ask for an inspection to verify the information submitted from the supplier. They may ask for additional laboratory tests. They will take the necessary actions to help them decide if they can trust the certification that their supplier is providing.

To make things more complicated, add food safety intelligence to the mix. At the core of ensuring food quality is the notion of risk assessment and mitigation. This is an extremely data-intensive process that involves collecting information and prioritizing risk based on a large variety of critical factors, which are different for each food product and process.

This brings forward the need for innovative technology solutions that will integrate data from multiple, heterogeneous distributed sources, process the data in almost real-time and use the results to support critical decisions that can ensure food safety; decisions made in a variety of quite diverse business roles, such as quality inspectors and procurement officers.

Here is where I have a call to action for you. At Agroknow, we have innovation in the making and we are looking for the early adopters that want to be the first to try it.

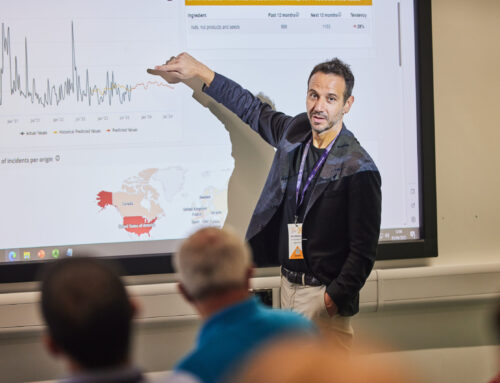

We already have a food safety analytics product called FOODAKAI. It scans the official announcements coming from food safety agencies covering over 170 countries around the world, on a daily basis. It continuously analyses more than 60,000 food safety incidents to extract critical information about 1.300 hazards and their serotypes, to calculate the risk associated with each hazard. It allows users to check the risk associated with a given supplier, ingredient or product recipe. It generates custom reports for food safety trends regarding a given product or particular types of incidents like food fraud.

What are we looking for? People that work in Quality Assurance and Procurement teams for food companies. People responsible for decisions like qualifying a new supplier or running quality checks for a product lot that has arrived on their premises.

What are we going to do together? We will be testing some really cool and innovative features that we are adding to FOODAKAI to help food buyers take fast and cost-efficient decisions. If you work with us, we will do things like:

- Dig deep into the food safety system you are using, specifically the food safety certificates that you request from your suppliers. We will understand the critical risk dimensions that each certificate is trying to control. We will focus on the ones that are important for your business. And we will specify which data should be collected and how risk assessment can take place, in an automated and real-time manner.

- Configure and set up custom Internet of Things (IoT) installations at the farm or facilities of selected suppliers. We will make sure that the sensor and control devices we are using, measure the critical data that your certificates require for a given product or process. We will collect and store both historical data about a product and live data streams that are broadcasted live for your eyes only.

- Discuss your ideas about some new FOODAKAI features. We will explore how you may remotely audit the suppliers that give you access to their data. We will also perform an intelligent risk assessment of both a candidate supplier and a product lot that has just arrived, combining historical and live data.

2018 was the year the first industry-driven platforms piloted the way that data may travel across the food supply chain in real-life applications. 2019 can be the year in which we will take a closer look at food certification data requirements and add intelligence to the mix.