My dear readers, let me introduce you to the Reynauds: the wonderful couple behind BriteScan LLC, a hardware-enabled SaaS company based near San Francisco that develops cutting-edge, affordable material verification solutions to enhance the quality and safety of products along the entire supply-chain.

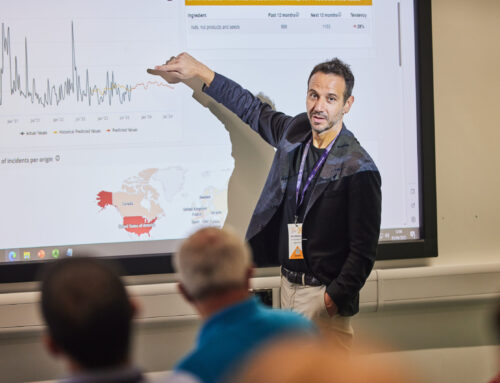

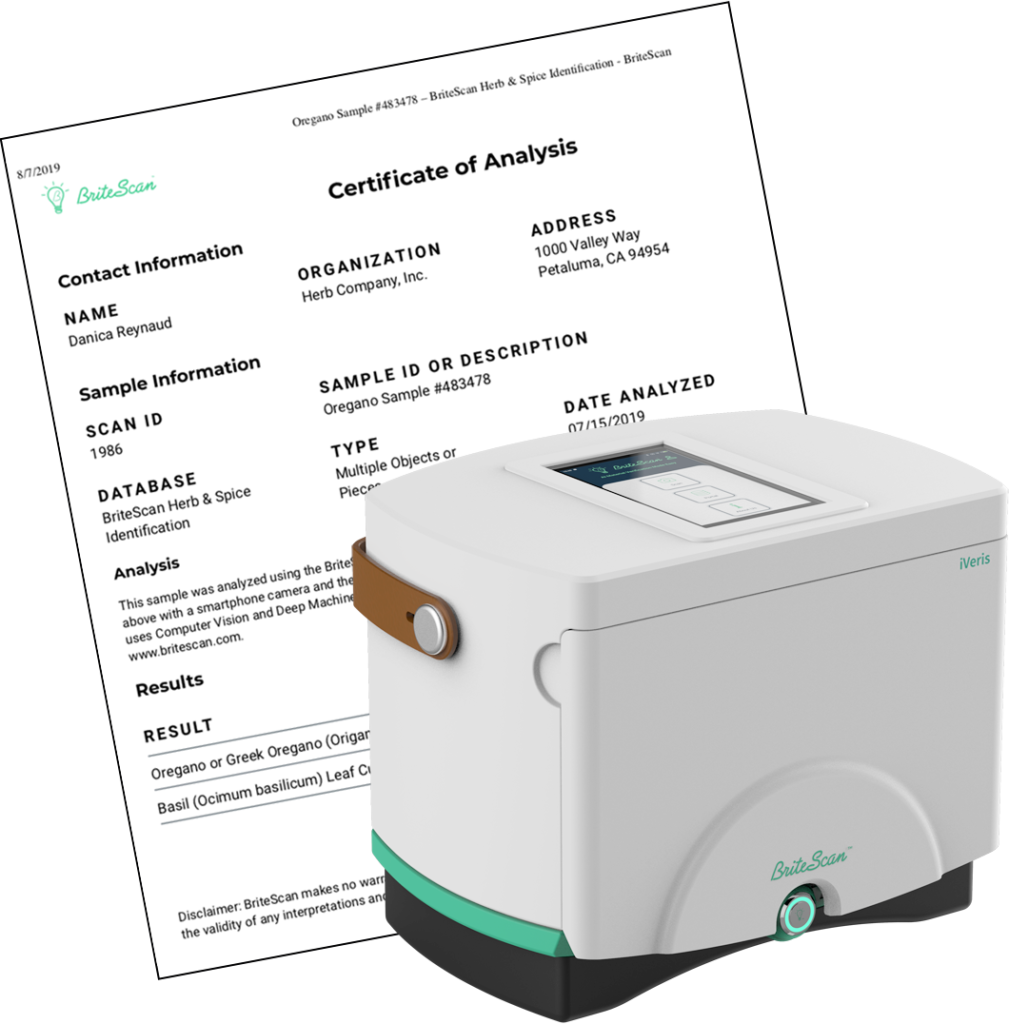

I first heard about BriteScan LLC and their iVeris™ solution from one of their fanatic users. Their “Digital Lab-in-a-Box” uses Artificial Intelligence and computer vision to scan, identify, and authenticate herbs, spices, fish, meat and other natural products. I find fascinating how easy, usable and efficient their solution seems to be. I also read that they are headquartered at the city Petaluma, known as the ‘Egg Basket of the World’ for its bustling egg industry in the early 20th century, and nowadays known as a foodie haven in Northern California.

After finding out about BriteScan, I reached out to Danica Reynaud, Co-Founder and Chief Science Officer. Danica is an experienced geneticist, botanist, and entrepreneur. She received a B.A. and Ph.D. in Integrative Biology from the University of California, where she conducted extensive research on ethnobotany, botanical taxonomy and plant genetics. She continued her research as a Postdoctoral Fellow at the National Museum of Natural History and Ancient DNA Lab at the Smithsonian Institution in Washington, DC.

She also brought in the discussion Dan Reynaud, Co-Founder and Chief Executive Officer of BriteScan. Dan is an entrepreneur with over 30 years experience in strategic business development, sales, and marketing. He spent nearly a decade providing corporate education solutions for Harvard Business Publishing servicing clients like; Google, Facebook and Hewlett Packard. Prior to this Dan worked as Director of Sales for Fatbrain.com which sold to Barnes and Noble where he became Director of Sales. Prior he co-founded the Digital Rights Agency – a music distribution company for over 350 indie labels, which sold to the Universal Music Group.

Prior to BriteScan, the Reynauds founded AuthenTechnologies LLC, the first DNA testing lab specializing in botanical authentication for the natural products industry, eventually acquired by the global standards and certification company NSF International.

Renauds, many people think that COVID-19 accelerates the digital transformation of the food supply chain. What is your opinion?

With the globalization of supply chains and increased food fraud and adulteration, we’ve recognized the need for the adoption of digital verification methods and cloud-based supply chain management systems for many years. Unfortunately, it has taken a tragic global pandemic for the food industry to realize the urgency for change.

COVID-19 and any other variants in the future necessitate a deeper look into the global food supply chain and openness to new ways of testing and tracing materials- and doing business. Innovative portable devices utilizing AI such as BriteScan’s patented iVeris™ and other mobile tools combined with secure cloud-based software systems present opportunities to expand the reach of digital technology.

Digital technologies streamline processes in a more uniform and cost-effective manner, allowing for democratization of testing across all stakeholders in the food supply chain, from the farmers and suppliers to manufacturers- and even consumers for the first time.

Which changes do you see coming in the market?

The need for better technologies to ensure the authenticity, traceability, and transparency of food supply chains has not changed. We will need to find ways to secure the supply chain in a dispersed, non-centralized fashion. Much like we see point of care testing in healthcare, this will be the case in the food supply chain due to changes in travel patterns, delays in transporting physical goods, and closure of brick-and-mortar businesses, including labs.

Post COVID-19 supply chain systems will be ripe for adulteration and current methods of monitoring and testing are outdated and unable to properly keep up with these concerns. Additional costs will plague the market, adding to the urgency of finding and using digital alternatives to traditional authentication and validation procedures.

There are several areas in which we see the marketplace needing to evolve to meet both current and post Covid challenges:

1) The supply chain needs to move from a traditional skip-lot testing model, to a more comprehensive testing structure in which all products can be thoroughly scanned for pathogens/viruses, authenticity, and contaminants all while improving the security of the overall data and supply chain- globally.

2) An increased productivity and consistency in testing with a reduction to overall cost, time, and expertise required to perform traditional lab-based analytical methods.

3) The need for portable tools that allow for accurate testing of physical goods directly from the field- or even at home- as travel and lab access is restricted.

4) An improved security posture that houses and maintains an accurate and validated data record to protect the food industry while creating a common standard that all food suppliers and customers must adhere.

5) Data transparency and the sharing of information related to incidents of fraud and adulteration in real time to prevent the reselling of compromised goods to other customers.

What do you hear from your clients? Which needs are they highlighting during this period?

Two years ago we launched BriteScan and developed the iVeris™ AI authentication platform. Our mission was to create an affordable and accessible digital solution to help increase the authenticity and quality of natural products, and the speed at which goods move through the supply chain. Our current clients have recognized this need far before the current Covid crisis. However, since COVID-19 we have experienced a rapid increase in demand for our product, from forward thinking companies- including traditional industries like teas and natural medicines- that realize new digital technologies are necessary to minimize disruptions to their supply chains. As we’ve seen physical audits and testing have been affected by the pandemic but these materials still need to move. Finding adequate supply of ‘in spec’ materials, especially food ingredients, is rapidly becoming more difficult.

Mobile, digital solutions can be deployed earlier in the supply chain by non-experts, so we are seeing current and prospective manufacturing clients looking to deploy the iVeris™ at their supplier level, rather than waiting for samples to ship to test in-house or send to third-party labs.

Since COVID-19 began, there has been a marked increase in articles both in mainstream media and trade journals highlighting the ongoing issues with adulteration and fraud. Our clients are looking at our iVeris™ solution not only as an internal quality control mechanism to reduce business and health risks, but also as an affordable marketing tool.

How do you respond to these needs? What is your company doing differently to serve your clients better?

BriteScan’s portable iVeris™ device is first of its kind to verify materials using simply a photograph that is instantly analyzed in the cloud using sophisticated AI computer vision algorithms. This allows even the most non-technical user in the field to have the same level of quality testing as the most technologically advanced companies. The quality and affordability of our solution allows us to democratize and mobilize authentication testing. Because of these attributes, we are well positioned to support the growing needs of the food- and other natural product- industries.

We are continuing to develop and refine our products to meet the unique needs of our customers, through both the hardware and associated cloud-based software. Through a series of strategic partnerships with technology companies we are able to expand our platform into a broader ecosystem to service industry and government agencies.

In your opinion, what is the digital technology that will be more extensively adopted by the market during the next 12 months?”

We’ve witnessed several new digital technologies come onto the scene in the past two years that have promised to revolutionize the industry namely to verify the movement of goods using blockchain. However, the reality is the physical goods inside the package must also be authenticated.

Digital technologies utilizing AI and computer vision that actually confirm the authenticity and quality of materials in real-time are critical. Otherwise, the issues of substitution and fraud will continue unabated. Our digital solutions can already deliver critical data in real time, so that decisions can be made immediately without the cost or delay of sending samples to a testing lab.

BriteScan’s iVeris™ can immediately be deployed and has proven successful for verification of identity, origin and quality of a wide range of food products and ingredients including herbs, spices, meats, fish, and oils. Because of its simplicity and affordability, it is possible that within only a few months, a company could create an entirely new alternative testing regime for a small fraction of the cost of traditional lab-based testing.

Like it or not, COVID-19 has digitally transformed human interactions and the way we conduct business. It will undoubtedly have a lasting effect. Adoption of these digital technologies is inevitable, as we realize the positive impact they make on keeping our personal and professional lives intact.