There are different ways in which food safety teams can stay informed about what is happening out there that could be critical for their supply chain.

For example, regularly checking official, trusted websites like the European RASFF portal and the US FDA recalls and safety alerts. Or subscribing to one of the services that send an e-mail alert when a food recall of interest takes place.

Welcome to the world of food risk monitoring tools – also widely known as horizon scanning and foresight tools.

For many years these terms were used to describe online services that scanned a large number of information sources in order to alert professionals as soon as an announcement of interest was published. Examples of prominent services widely used for this purpose include FoodTrack Inc., the IFS Trend Risk Monitor, and FERA’s HorizonScan.

In an era of AI and predictive technologies for food risk prevention, available options for performing risk monitoring across the food supply chain have become even more extensive and powerful.

Let me walk you through the main ways in which food companies address this need.

(Photo by Pavan Trikutam on Unsplash)

Option 1: Rely upon suppliers to inform them about a critical incident

The most traditional way to be informed about an incident that concerns their suppliers: expecting that someone will pick up the phone (or drop a line), as soon as something important happens. They are not proactively on the lookout for what is happening that could be critical for their supply chain.

This approach assumes that they fully trust their suppliers and that, if something happens, they will be notified on time.

Option 2: Regularly monitor 2 or 3 official sources of information in the markets of interest

This means devoting less than a couple of hours every week to visit important, official websites (such as RASFF) to check if something new has been announced. A routine that keeps them up to date with credible, verified information. Particularly useful if their geographical and jurisdictional scope of interest is covered by these specific official authorities.

This approach assumes that official authorities have everything that matters to a food company at their web sites.

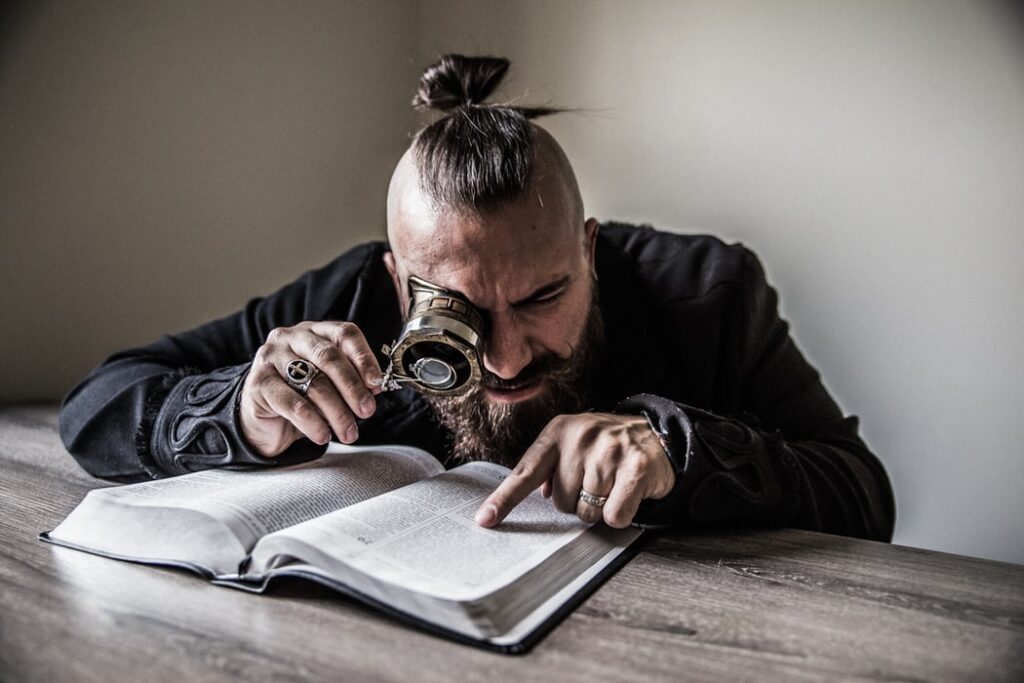

Option 3: Systematically devote time to research numerous online sources about emerging issues and hazards

This is where they seem to be more proactive and extensive in their information search. Apart from the 2 or 3 major global authorities, they have also bookmarked a number of other information sources that they systematically research. Very often, these include:

- Inspection reports announced by local authorities nearby their critical suppliers

- Web sites of official authorities at each and every country in which their products are being distributed

- Results of border inspections or residue monitoring programs in these countries

- Trusted food safety news sites

This approach can really keep them up to speed with what is happening. It assumes that they have time and people and time to allocate to such a systematic desktop research.

(Photo by Bertrand Bouchez on Unsplash)

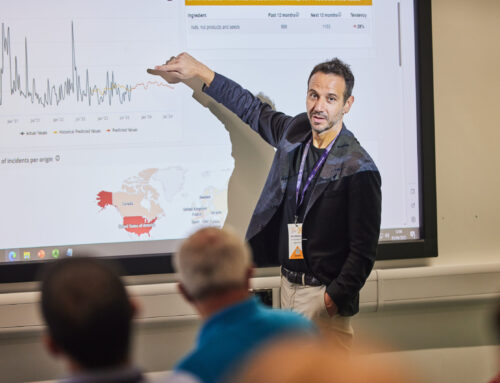

Option 4: Use a 3rd party service that provides notifications about announced incidents as well as predictions about expected ones

Whether they choose one of the traditional horizon scanning tools or go for a modern AI-powered dashboard, food supply chain companies find plenty of 3rd party solutions available – and for every budget.

This lets others do the dirty job of scanning, processing, combining and extracting meaning out of tenths or hundreds of information sources. Saves lots of time and resources, especially if the selected tool also predicts emerging risks and upcoming incident trends so that it gives them a glimpse of the future.

This approach assumes that they have explored several available options and have chosen a solution that fully covers their company’s needs.

Option 5: Develop an internal software that monitors a variety of online sources, provides with alerts & notifications, and implements AI algorithms that predict upcoming issues

The preferred solution for large food manufacturers that have the appropriate resources, senior management buy-in, and a digital transformation agenda.

Software development focuses only on the modules and features that are important for their company (although learning from what others do in the industry usually helps). It reduces the risk of relying upon 3rd party suppliers for an operation that is critical.

This approach assumes that, apart from the required resources, the company demonstrates patience and persistence. In my experience, organizational data science capabilities and solutions grow and mature with time.

So, looking at all these different ways of implementing a food risk monitoring strategy in a food company, where is it that AI & predictive analytics can make a difference?

(1) At horizon scanning & alert investigation

- Web site crawling software can automate data gathering and processing, monitoring about updates in near real time

- Text mining algorithms can understand which products, ingredients and suppliers are involved in a reported incident

- Deduplication algorithms can ensure that each report is unique, aggregating multiple alerts into one, more complete data record

(2) At identifying rapidly emerging issues

- Time-series forecasting can estimate how many incidents per product or ingredient category should be expected in the weeks or months to come

- Prediction models can estimate on whether specific risks have a high or low probability to occur

These are only a few of the many ways in which AI-powered technologies can significantly expand the capabilities of food risk monitoring systems.

Want to know more about where your company stands in terms of food risk monitoring? Take this free online self-assessment test.